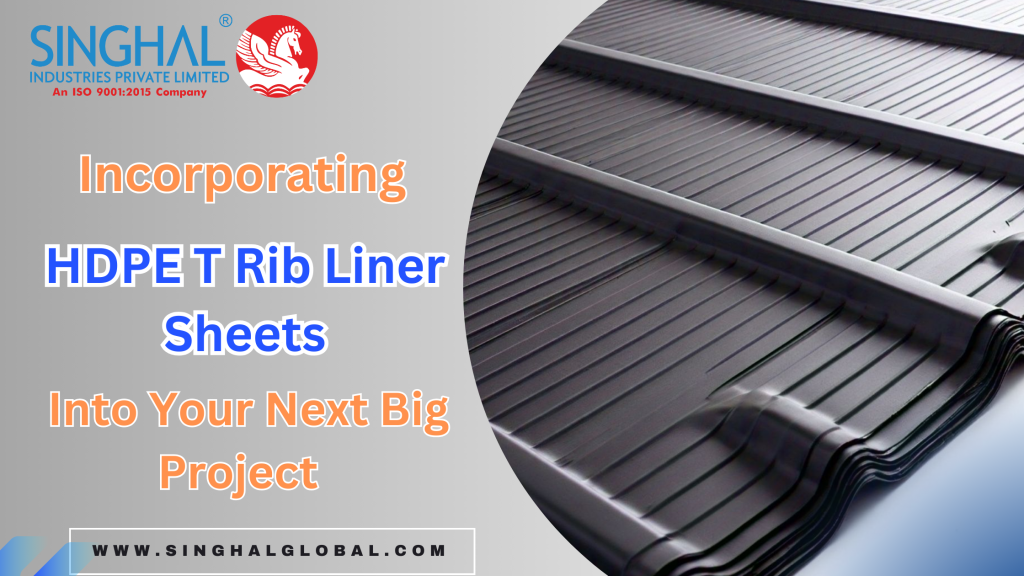

When developing large structures or considering utilizing industrial solutions, choosing proper materials is crucial to extensiveness, efficiency, and expense. The HDPE T Rib Liner Sheets are one of the many advanced materials obtainable in today’s markets with outstanding features and variety. These HDPE sheets are T ribs reinforced and have been extensively used in tunnel, canal, tank and any other construction that requires high degree protection against leakage and abrasion.

This article will explain why HDPE T Rib Liner Sheets are increasingly used in engineering and project management, how they improve performance, how important it is to find reliable HDPE T rib liner manufacturer.

What Are HDPE T Rib Liner Sheets?

HDPE T Rib Liner Sheets are designed from high-density polyethylene (HDPE) with t-shape ribs system. These ribs also offer higher pullout resistance therefore giving better bite to concrete or other substrates for longer periods.

Used in many types of industries for its chemical resistance coated as well as waterproof sheets for many applications desired. From most of the leading HDPE T Rib sheet suppliers who supply high-density polyethylene T Rib sheet available, customers can order in bulk options based on size and thickness.

Why Incorporate this Sheets Into Your Project?

1. Exceptional Durability

HDPE T Rib Liner Sheets is thus more appropriate for use in conditions where it is likely to be exposed to chemicals, ultraviolet radiation and high or low temperatures. Baron says this durability means that the project components will be useful for several decades and are not likely to fall apart. For instance when using wastewater treatment tanks corrosion as well as leakage is controlled by lining the structure with HDPE T Rib sheets.

2. Superior Bonding Strength

These sheets are equipped with T ribs which allow a mechanical interlock with concrete and such production is desirable for tunneled, reservoired or otherwise structures requiring a sturdy bond. T ribs give a features of added strength by making sure that the element does not detach at high pressures.

3. Chemical and Corrosion Resistance

HDPE material has excellent resisting properties toward chemicals, acids, and alkalis and thus can be suitable where there is tendency for exposure to aggressive material.

4. Waterproofing Capability

HDPE T Rib Liner Sheets are most commonly used in waterproofing projects. This characteristic ensures that water does not penetrate building structures thus a barrier to water related ravages.

5. Cost-Effective and Long-Lasting

While the initial cost of purchasing HDPE T Rib sheets remains relatively high than the traditional liners, its benefits such as durability and easy to manage costs puts this product as an economical solution.

Applications of this Liner Sheets

1. Tunnels

HDPE T Rib sheets provides watertight protection and enhance structural strength of tunnels and can withstand even the most pressurized environment.

2. Canals and Reservoirs

For irrigation and water storage purposes the use of these sheets offer a reputable water proofing and protection even against erosion and seepage.

3. Wastewater Treatment Plants

HDPE T Rib liners are applied in tanks and basin constructions so as to protect them from chemical corrosion to enhance their operational durability.

4. Industrial Tanks and Silos

To companies that handle corrosive chemical or material, these sheets act as skin to avoid leakage or structural compromise.

5. Retaining Walls and Foundations

Through increasing the protection cover from moisture, HDPE T Rib sheets also boost the endurance of retaining walls and building foundations.

Benefits of this Liner Sheets

- Enhanced Mechanical Bonding: T ribs offer proper adhesion with concrete surface thus guaranteeing that they do not come off easily.

- Superior Waterproofing: Reduces leakage and water infiltration in structure in areas of the critical structures.

- Chemical Resistance: Resists many chemical agents because of its ability to withstand them hence is be suitable for use in industries.

- Flexible and Lightweight: They are transportable and when delivered get installed very fast thus reducing oncalls and human efforts.

- Low Maintenance: Needs low maintenance, hence cutting down on future costs in the course of operation.

- Eco-Friendly: Constructed from recycled material so as to promote use of environmentally friendly construction materials.

Installation of this Sheets

Step 1: Surface Preparation

Choose a surface to place the product and make sure the surface is clean, smooth and has no particles on it for it receive the adhesive well.

Step 2: Aligning the Sheets

Lay down the HDPE T Rib Liner Sheet on to the surface with the T ribs standing up perpendicular to the concrete block work.

Step 3: Securing the Sheets

Attach the liner to the substrate using suitable adhesives, fasteners or other particular equipment required.

Step 4: Concrete Application

Spread concrete over the liner and make sure it adheres well to the T ribs in order to give a sound foundation of the liner.

How to Choose the Right HDPE T Rib Liner Sheets

- Material Quality: Choose high quality HDPE T Rib sheet to obtain the high performance and durability of the sheets and always select it from reputed manufacturers.

- Thickness and Rib Spacing: Choose from an adequate thickness and rib profile that will suit your structural and environmental requirements on your job.

- Customization: Seek for those manufactures who offer customized solutions regarding size, thickness and etc.

- Cost and Availability: Search for the best prices among different suppliers in order not to overpay for really cheap products.

Conclusion

HDPE T Rib Liner Sheets are highly effective today’s construction and industrial branding and challenging construction development. The life span, chemical resistance and best waterproofing features make them suitable to be utilised in tunnel and canal linings and inner surfaces of industrial tankage and foundations.

To have good result on your project, you got to do your best to look for the best suppliers for your HDPE T Rib liner. whether you are carrying out a massive infrastructure construction, or undertaking a specific industrial project, integration of HDPE T Rib Liner Sheets will mean costs are slashed, time reduced and results optimized.

Frequently Asked Questions (FAQs)

Q.1 Do HDPE T Rib Liner Sheets provide insulation?

It should however be noted that although sheets of HDPE T Rib are not made for thermal insulation, they provide moderate thermal resistance to shield structures against high temperature stress.

Q.2 Are HDPE T Rib Liner Sheets easy to install?

Yes, thus we have lightweight and flexible HDPE T Rib Liner Sheets which are easy to handle and install. This makes the installation easier and well fixed in the right places that it is needed.

Q.3 How long do HDPE T Rib Liner Sheets last?

HDPE T Rib Liner Sheets has an average design life of several decades in average conditions and environment. That means that their usage makes them the best long-term solution.

Q.4 Can HDPE T Rib Liner Sheets be customized in size?

Yes, most of the HDPE T Rib liner manufacturers and supplier would additional provide customization services in term of size, thickness and design to fit different projects.