Geocomposite are a series of geosynthetic materials that serve several roles in geotechnical, environmental, and civil engineering applications. They are essentially a blend of two or more geosynthetic materials, e.g., geotextiles, geogrids, geomembranes, and geonet, or sometimes even other products like deformed plastic sheets or steel cables. This dual synergistic interaction enables Geocomposite to present improved performance and usually a more cost-efficient and effective solution when compared to using single geosynthetic. Singhal Industries is known as best Geocomposite Manufacturer in Gujarat.

Geocomposite is a produced material that consists of two or more distinct geosynthetic elements, or a geosynthetic and another product (e.g., steel wire, plastic film). The basic concept in designing a geocomposite is to make use of the special strengths of each constituent material to produce multiple functions within one product in order to improve performance and usually provide a less expensive solution in civil engineering and environmental uses.

Think of them as "multi-tasking" geosynthetic. Instead of laying down a particular coating for filtration, then another for drainage, and another for strengthening, a geocomposite can accomplish all or several of these functions at once.

Geotextiles: Permeable materials (woven or non-woven) for filtration, parting, shield, and some strengthening.

Geogrids: Grid-like reinforcing systems with high tensile strength.

Geomembranes: Waterproof sheets utilized as liquid or gas barriers.

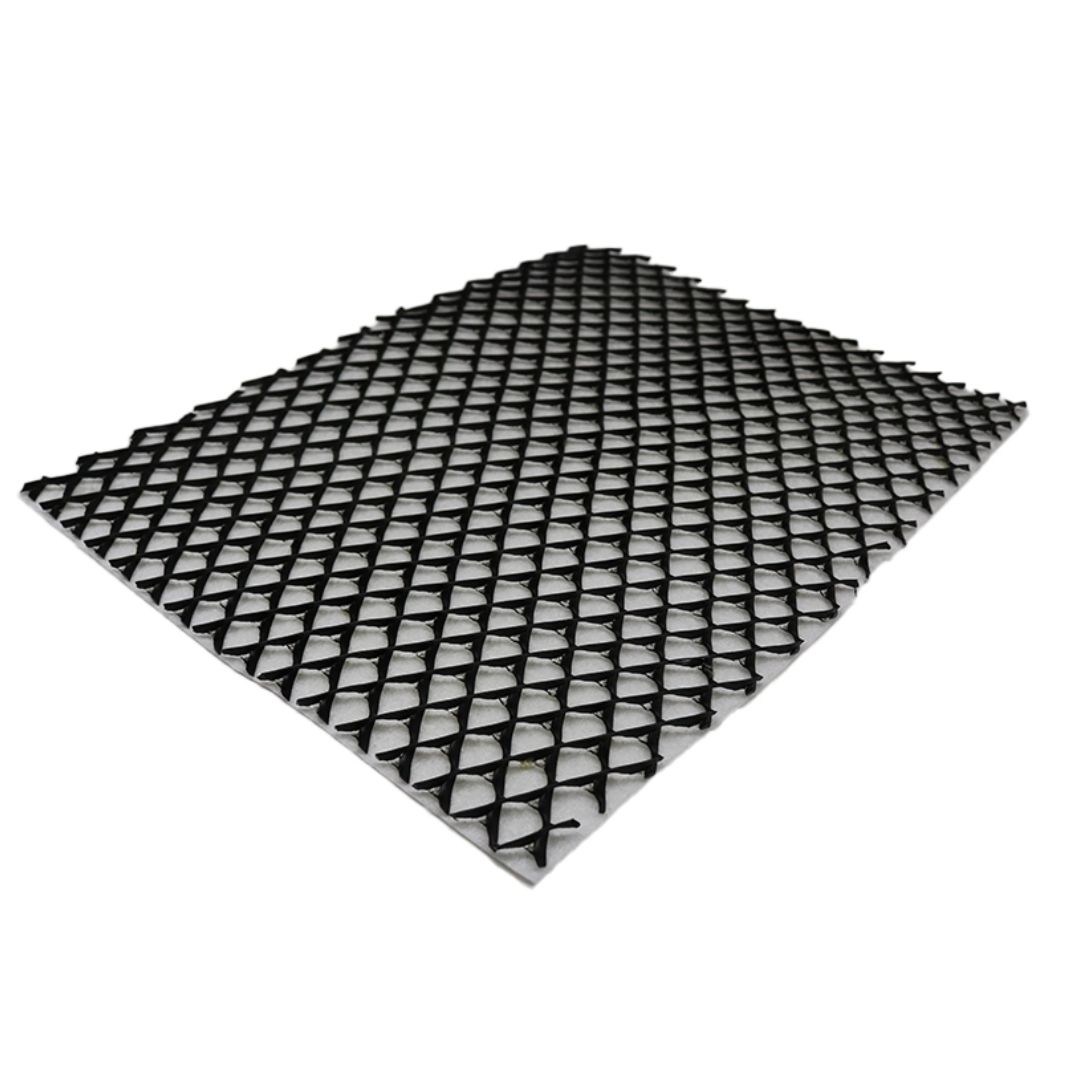

Geonet: Three-dimensional internet-like configurations for powerful in-aircraft drainage.

Polymer Cores (Drainage Cores): Engineered plastic sheets (e.G., dimpled, fluted) that form a void area for heavy liquid flow.All these components are bonded together by various manufacturing processes such as lamination, thermal bonding, or mechanical interlocking.

Geocomposite may integrate a number of the five fundamental geosynthetic roles:

Seggration: Avoiding the mixture of different types of soil.

Reinforcement: Focus on tensile strength for soil or other fabrics.

Drainage: Water or gas so that the material can pass inside the aircraft.

Connection/barrier: to create an impenetrable cover to avoid movement of fluid or gas.

Geotextile-Geonet Composites: Geotextile on one or each surface of a geonet, typically applied for drainage (e.G., landfill leachate series, behind retaining walls).

Geotextile-Geomembrane Composites: Geotextile masking a geomembrane, applied for barrier and protection (e.G., landfill liners, pond liners).

Geotextile/Polymer-Core Composites (Drainage Composites): Geotextile enveloping an established polymer middle, high-quality for excessive-capability drainage (e.G., prefabricated vertical drains for soil consolidation, wall drains).

In effect, geocomposites offer a price-powerful, revolutionary, and environmentally friendly response to problematic geotechnical issues, frequently substituting for traditional granular merchandise and optimizing construction approaches.

The intrinsic characteristic of Geocomposite is that they can combine multiple functions into a single item. These functions are generally:

Drainage: Geocomposite with a high flow rate core (e.g., geonet or a structured polymer core) and filtered by one or both sides of geotextiles are very good at draining water, leachate, or gas in-plane.

Filtration: The geotextile portion of a geocomposite serves as a filter, letting fluids pass through but keeping out fine soil particles that could clog the drainage core.

Separation: A geocomposite (usually with a geotextile) placed between two different layers of soil prevents intermixing and keeps each layer intact with its specific properties.

Reinforcement: Geocomposite with geogrids impart tensile strength to the soil, enhancing its stability and load-carrying capacity, especially in reinforced walls, slopes, and road bases.

Containment/Barrier: Geocomposite with a geomembrane component serve as impermeable barriers preventing the flow of liquids or gases, essential in landfill liners and pond usage.

Protection: The geotextile components may safeguard other susceptible elements, such as geomembranes, from damage by puncture or abrasion by overlying materials. There are various Geocomposite Exporters in Delhi

Various kinds of Geocomposite are created by integrating a particular geosynthetic:

Geotextile-Geonet Composites: These are usually applied in drainage, with the geotextile working as a filter and strainer, and the geonet as the drainage path.

Geotextile-Geomembrane Composites: In these, geotextiles shield the geomembrane from harm while possibly providing a path for drainage for gases or fluids on one side.

Geomembrane-Geogrid Composites: When geomembranes and geogrids are produced from the same compatible material (e.g., HDPE), they can be joined to form an impermeable barrier with increased strength and resistance to sliding.

Geotextile-Geogrid Composites: These take the separation and filtering properties of geotextiles and couple them with the reinforcement properties of geogrids, which find application in soil reinforcement and erosion protection.

Geocomposite provide a myriad of advantages over other engineering solutions and even single geosynthetic:

Multi-functionality: The biggest advantage is their capacity to carry out more than one function at a time, making designing and constructing easier.

Reduced Material Usage: By acting as multifunctional components, they tend to save on the use of several layers of conventional granular materials (such as gravel or sand), resulting in a high saving in excavation, material purchase, and haul costs.

Space Saving: Their slender thickness, particularly in drainage use, saves precious space in comparison to thick granular drainage layers.

Faster Installation: Geocomposite are generally provided in roll form, which makes them lightweight, convenient to handle and install, resulting in faster installation schedules and lower labor costs.

Enhanced Performance: The synergistic benefit of the aggregate components often leads to better performance in terms of drainage ability, strength, and durability under diverse environmental conditions.

Environmental Benefits: Minimized excavation and transportation of materials reduce the carbon footprint. They also help in environmental protection uses such as landfill lining by preventing contamination.

Chemical and Biological Resistance: Having been Geocomposite Manufacture in Gujrat from synthetic polymers, Geocomposite are resistant to the majority of naturally occurring chemicals, acids, alkalis, and biological decay, making them provide long-term performance.

Consistent Quality: Products that have been manufactured in factories provide consistent quality and performance, unlike natural products that can fluctuate. Geocomposite Price in India are very reasonable at Singhal Industries.

Geocomposite have various applications in all areas of civil and environmental engineering:

Drainage Systems:

Roads and Railways: Subgrade drainage to avoid water accumulation, reduce frost heave, and provide pavement layer stability.

Landfills: Leachate collection and gas venting systems, providing effective removal of toxic liquids and gases.

Retaining Walls and Bridge Abutments: Discharging hydrostatic pressure behind structures, avoiding damage.

Tunnels and Underground Structures: Draining seepage water to safeguard waterproofing membranes and decrease pressure.

Sports Fields and Landscaping: Allowing for quick and effective drainage to avert waterlogging.

Slopes and Embankments: Stabilizing soil against erosion due to rainfall and wind, sometimes in combination with vegetation.

Riverbanks and Coastal Areas: Offering a defense barrier against water flow and wave action, supporting shoreline protection.

Road and Railway Embankments: Building up the strongness and toughness of the underlying ground, resisting rutting and breaking.

Foundations and Subgrades: Raising the load-carrying capacity and minimizing differential settlements.

Reinforced Soil Walls: Creating internal drainage for low-permeability backfill soils.

Landfill Liners and Caps: Creating impermeable barriers to prevent leakage and gases from escaping, safeguarding groundwater against contamination.

Pond Liners: Stopping seepage in artificial ponds and reservoirs.

Contaminated Site Remediation: Utilized as components of systems to contain or treat contaminated soils.

Prefabricated Vertical Drains (PVDs): Facilitating consolidation of soft, cohesive ground to shorten settlement time considerably.

Specifications for Geocomposite differ greatly based on the envisaged application and kind of geosynthetic to be combined. Still, general parameters taken into account are:

Material: Usually polypropylene (PP), polyester (PET), or high-density polyethylene (HDPE) for the individual unit.

Thickness: Varies from a few millimeters (e.g., drainage Geocomposite 4-8 mm) to some centimeters, depending on the core configuration and number of layers.

Flow Capacity (Transmissivity): A key parameter for drainage Geocomposite, referring to the ability of fluid to flow in the plane of the geocomposite under given hydraulic gradients and normal stresses (e.g., 10−3 to 10−4 m2/s).

Compressive Strength: Especially for drainage cores, reflecting capacity to resist overburden pressure without sacrificing flow capacity (e.g., 300-600 kPa).

Puncture Resistance: Essential for protection layers, tested to standards such as ASTM D4833.

Grab/Tear Strength: Reflects the material's resistance to tearing and pulling forces..

Chemical Resistance: Suitability for the anticipated chemical environment (e.g., landfill leachate).

UV Resistance: Critical for uses where the geocomposite is exposed to sunlight during installation or in its final position.

Roll Dimensions: Width (e.g., 2-4 meters) and length (e.g., up to 100 meters or more) to ensure efficient handling and installation.

Certification: Compliance with applicable national and international standards (e.g., MORTH specifications in India, ASTM, ISO standards).