In fast-moving industrial manufacturing, strong products and efficiency aren’t just desired, they’re required. One of the materials that has quietly transformed numerous industries can be described as an HDPE (High-Density Polyethylene) sheet. In chemical processing, agriculture, marine construction, or packaging, HDPE plastic sheets have proven their versatility and dependability.

It could appear like a standard plastic sheet. Don’t be deceived. It’s a powerful material cherished by contractors, engineers, and technicians from all over India and around the globe.

Let’s find out the factors that make HDPE plastic sheet makers feel proud of their product and why more businesses are shifting from traditional products, such as metal or wood, to HDPE rolling solutions for plastic sheets.

What makes HDPE Sheets Different?

The High-Density Polyethylene or as it is abbreviated HDPE is a thermoplastic which is produced using petroleum. Its strength-to-density rate as well as resistance to water-, chemicals-and impact are well-bolstered, which is why it is commonly known. This is the reason HDPE plastic sheet makers continue to witness a rise in the number of orders coming from industries in which performance is more important than appearance.

One of the most striking features? Neither do they corrode or rust, or absorb water. This makes them a top choice for areas that require endurance.

Imagine a plant for food processing that sprays water continuously with temperature fluctuations and high foot circulation. Wood will begin to rot. Metal could get rusty. But HDPE? It stays solid, unaffected.

Industries and applications that make use of HDPE plastic Sheet Roll

The number of industries relying upon Hdpe plastic sheet roll is a long one; however, let’s focus on some that demonstrate the incredibly flexible nature of this product:

1. Construction and Infrastructure

Builders now use HDPE sheets for forms, foundation lines, pipes, and barriers. It’s less expensive and lighter than conventional metal sheets and it’s much easier to cut shapes, cut, and then install. In humid regions such as Kerala as well as the coastal belts that comprise Tamil Nadu, HDPE doesn’t change shape like wood, nor corrosion as steel does.

2. Boating and Marine

This is a surprise: HDPE floats! It’s not just waterproof; it can also resist saltwater corrosion. This makes it perfect for dock bumpers, as well as Marine wall panels. States with coastal regions like Goa along with Gujarat have seen an increase in HDPE use to maintain docks.

3. Chemical Processing

HDPE gives the chemical resistance required to protect storage containers, trays, or fume-hoods in industries that deal with acids and alkalis. HDPE doesn’t break down when exposed to harsh chemicals, making it more resilient than most plastics.

4. Agriculture

Is it ever that you saw that green floor covered by plastic sheets? It’s likely HDPE. From irrigation canals and seedling trays to HDPE, it is helping Indian farmers maintain their operations safely, efficiently, and durably.

5. Logistics and Packaging

Due to strength and flexibility, bins, pallets, containers, etc. are prepared in HDPE. It can take a beating in transport, yet it looks brand new.

A Real-Life Look: A Factory Manager’s Shift from HDPE to HDPE

Sunil Sharma, a factory manager in Haryana, remembers when his company switched between plywood and HDPE for their flooring in warehouses.

“We had to spend thousands of dollars to repair cracked and warped wood floors every couple of months. Maintenance has since slowed down to minimal since we adopted use of HDPE sheets. It’s been over 18 months since the switch, and the sheets appear brand new. The installation was straightforward.”

Feedback of this kind is not uncommon. This is why HDPE plastic producers in India are now working around the clock to meet the industrial demand.

Cost-savings and Customization

One of the most prominent reasons behind the material’s popularity is its flexibility. If you require a smooth surface for food packaging or an anti-slip flooring surface, HDPE delivers.

How much is it? The cost per square foot of HDPE could appear more expensive than plywood or PVC at first. However, please consider its lengthy duration, low maintenance, and fewer repairs, making it more affordable over the long haul.

Large orders of HDPE plastic sheets directly from the Hdpe plastic manufacturers can drastically reduce the price per unit.

Sustainability Angle Better for the Earth?

It’s here that things become exciting. HDPE is entirely recyclable. In factories trying to minimize their environmental footprint, changing to HDPE sheets is an increasingly popular choice.

Although it’s not biodegradable, it’s durable and can be degraded and used again, which is an excellent thing for sustainability.

Health and Environmental Benefits

At a time when businesses face pressure from the government to decrease emissions, HDPE shines again:

- Recyclable HDPE is 100 percent recyclable and made of post-consumer materials.

- Non- toxic: It does not give hazardous gases in normal conditions.

- Long life: Lowers the requirement for regular replacements.

This is a sustainable aspect, which is why numerous green construction projects in India choose HDPE for partitions in the interior furniture, partitions, and panels.

Conclusion

In a time where industries are pushed to be more efficient, environmentally sustainable, and affordable, HDPE sheets provide an ideal material that checks every box. If you’re shipping, building, expanding, or fixing, HDPE is the quiet, silent player in the background that helps everything run more smoothly.

If you’re searching for trustworthy HDPE plastic sheet producers or are unsure of the best high-quality HDPE sheet for use in your business, do not hesitate to contact Hdpe plastic sheet manufacturers. With the growing emphasis on India’s industrial development, you’ll have numerous options tailored to your requirements.

Frequently Asked Questions (FAQs)

Q1. Are HDPE sheets water-proof?

Absolutely. HDPE is impervious to any form of water, whether fresh salt, chemical-laden. This is why it’s commonly employed in the marine and chemical industries.

Q2. What are HDPE sheets employed to do?

Everything from flooring to packaging containers, machine parts tanks cutting boards, and many more. The range of options is unparalleled.

Q3. Is HDPE appropriate for marine applications?

Yes! It withstands saltwater, floats and isn’t damaged by corroding. A lot of coastal industries utilize HDPE as docks and boat components, as well as barriers for protection.

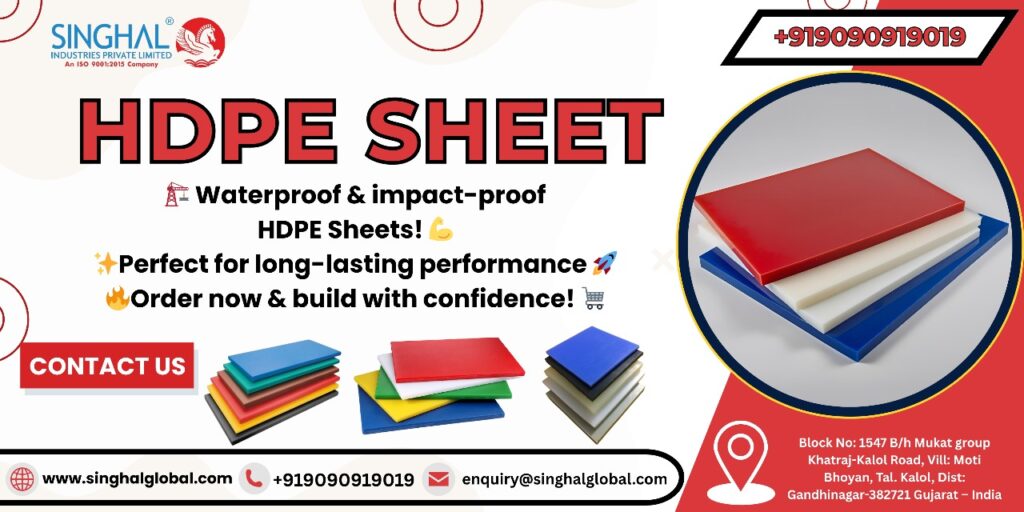

Q4. Who is the largest supplier of HDPE Sheet ?

Singhal Industries is one of the largest suppliers of HDPE sheet, they provide durable quality flexible universal products for use in industrial, agricultural and construction applications.

Q5. Can HDPE Plastic sheets substitute for metal or wood?

Yes most likely the products already come with. They are lighter, weather protected and long-term they tend to be cheaper.