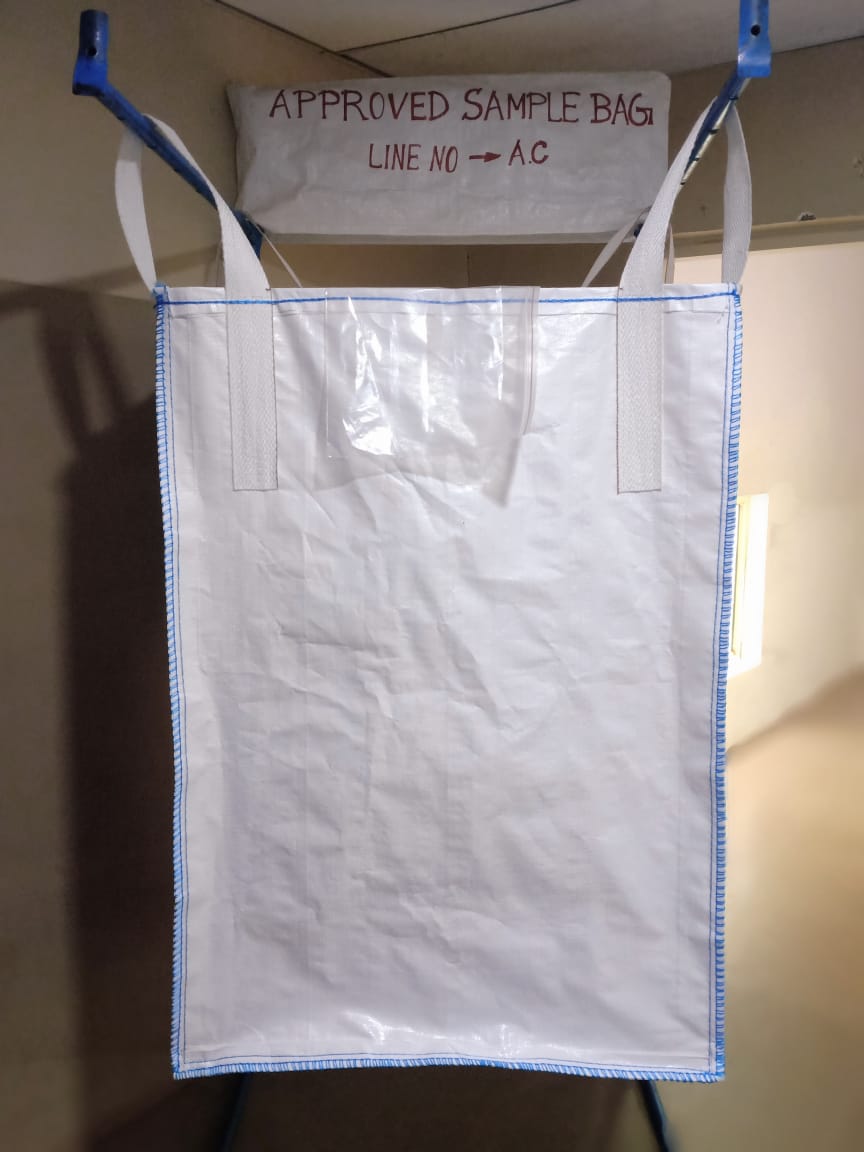

FIBC Bulk Bags are a type of plastic packaging typically used in shipping and storing bulk materials such as foodstuffs, chemicals, and lumber. FIBC Bulk Bags are made out of high-density polyethylene. FIBC Bulk Bags are often used for shipping bulk materials, including food, chemicals, and lumber. They are used to transport large amounts of products in a single shipment, saving time, money, and space.

FIBC Bulk Bags can be deployed in various ways depending on the use case or need of the customer. For example, they are transporting foodstuff due to the potential health risks if exposed to oxygen during shipping. Additives in some chemicals could cause plasticizers to react with other substances while in storage. Since FIBC Bulk Bag are not recyclable, they would be disposed of alongside other waste.

These use cases have helped shape FIBC Bags into the product we are today. There is no need for additional bulk materials like pallets and forklift access in place because they can fit inside of a standard truck or trailer. The core of what makes our bags so unique and innovative is the FIBC Bags itself.

Our product is designed to be easy and maintain the highest quality standards possible. We design a product that has been through several rigorous tests and experiments to ensure that it can last the life of your bag. Our bags are made of high-grade polyethylene film, providing the best durability of all other products. With no additional staples or tape needed for assembly, our bags are truly unparalleled in this field since there is no more time wasted when using other bulk packaging brands. It also comes with a superior barrier against dirt, dust, and gas and displays excellent UV resistance from various types of light.

Singhal Industries Pvt. Ltd. is the most famous name in the industry of FIBC Bulk Bag. They are regularly manufacturing quality Flexible Intermediate Bulk Containers. They also deliver FIBC Bulk Bags in the United States, Australia, Canada, United Arab Emirates, and United Kingdom.

FIBC Bulk Bags are a packaging solution made of flexible film. The bags are lightweight and can be easily transported. They come in various sizes and shapes, allowing for customisation of the packaging. FIBC Bulk Bags are perfect for shipping bulk items such as nuts, bolts, screws, and other small parts. What are the benefits of FIBC Bulk Bags? The bag's flexibility makes it easy for the product to move, even with the use of custom tools.

The bags have a smooth, high-quality finish and a tight seal to prevent leaks or spills. The bags can be filled with up to 1400 pounds and offer good protection against exposure to moisture and temperature extremes. The bags are typically used as shipping packaging and can be used for pharmaceutical, food, and beverage applications.

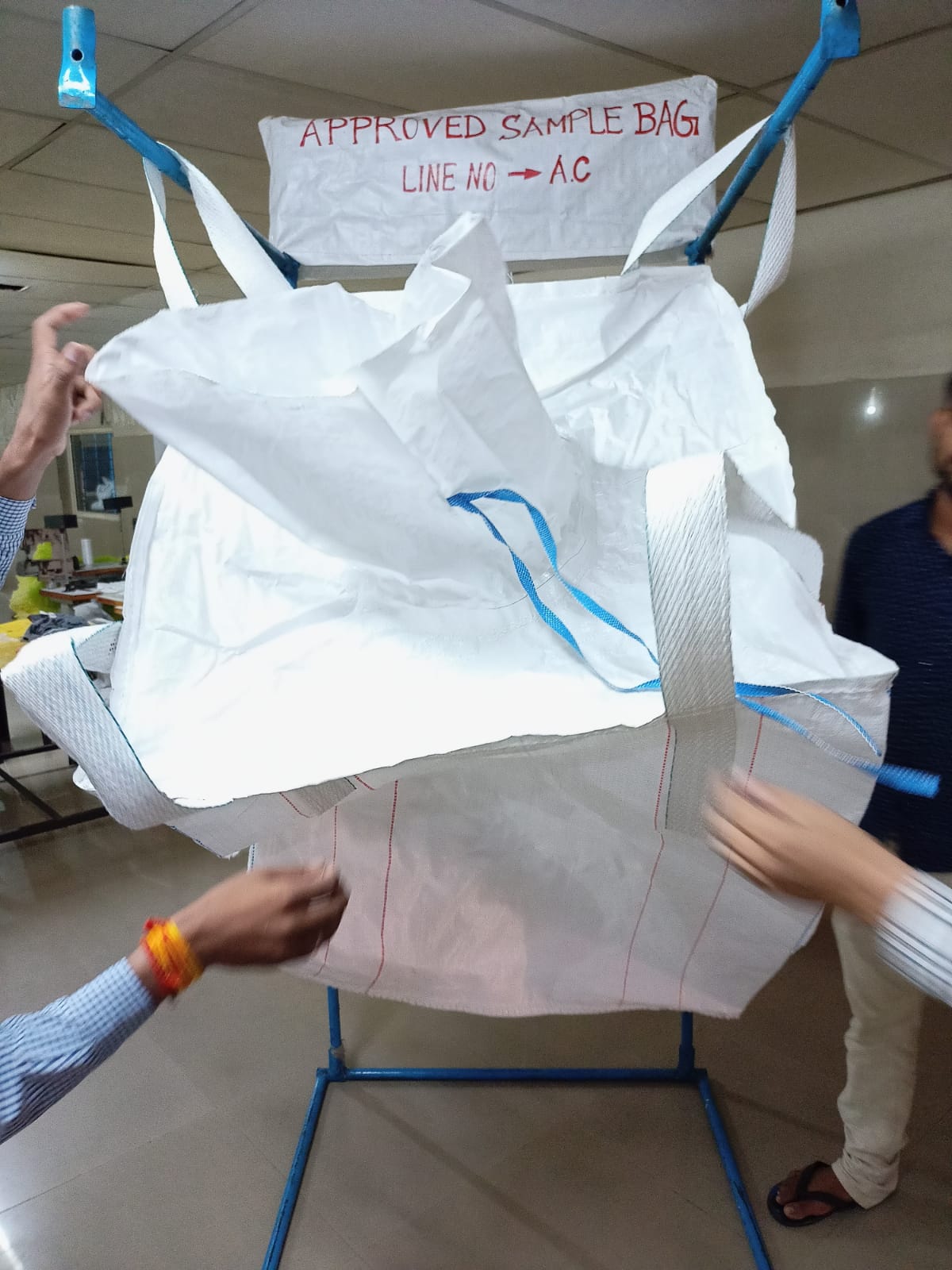

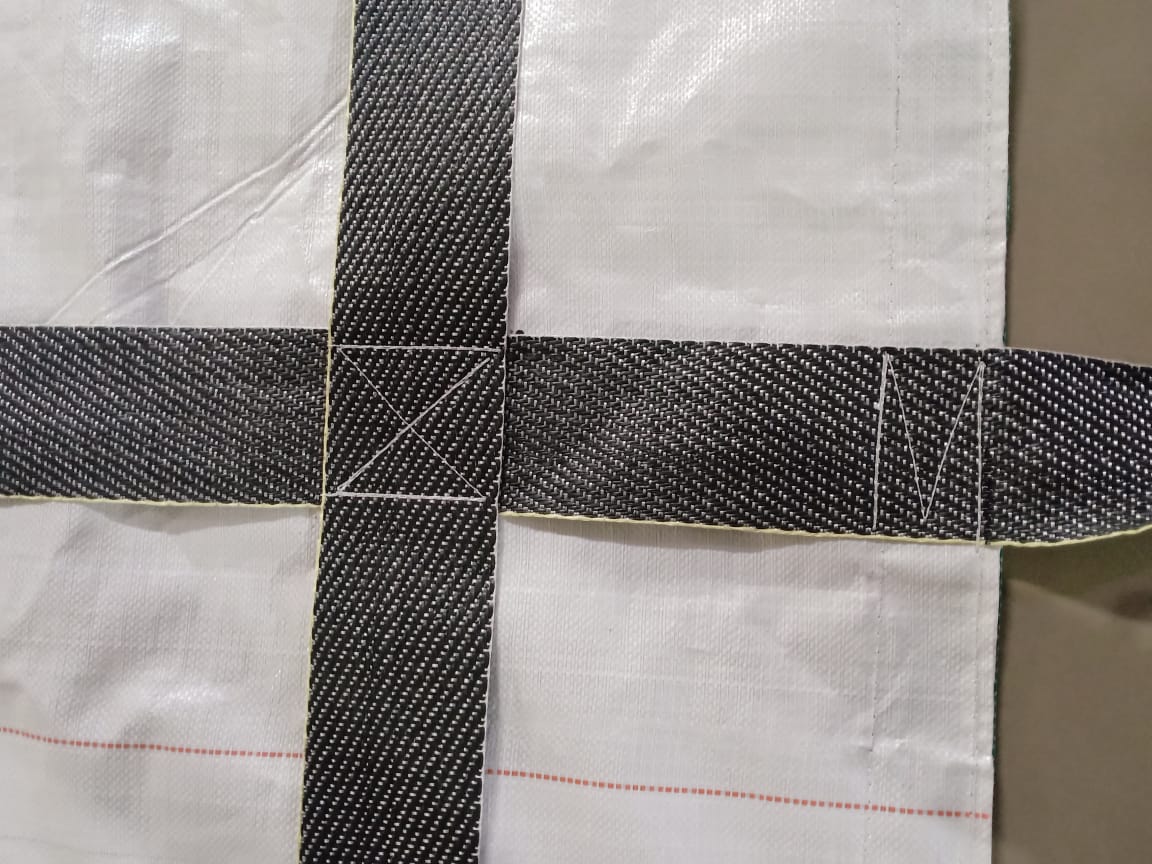

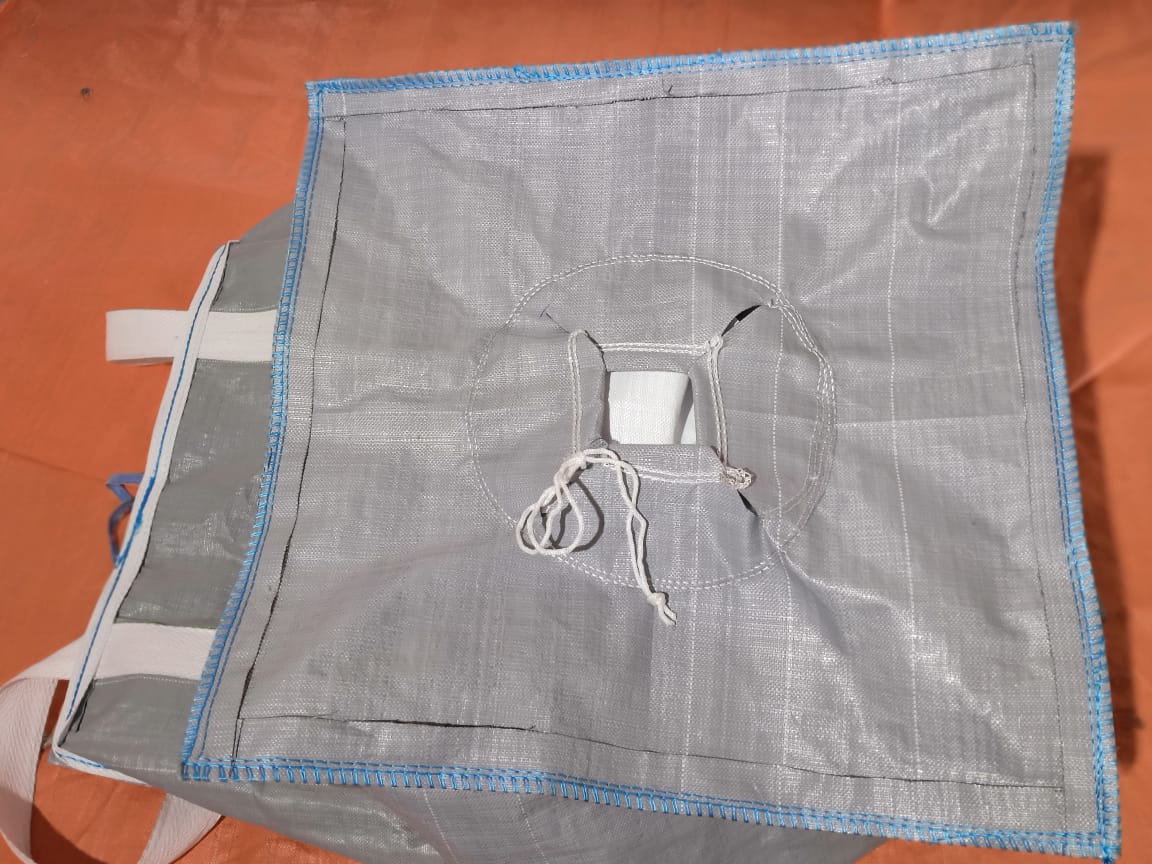

FIBC Bags features a high-density level, eliminating the need for heavy boxes. Even in highly corrosive environments, the bags offer excellent protection for sensitive products. FIBC Big Bags use strong materials that resist tears and punctures from impacts or scratches from handling equipment. They can be easily machine-sewn using hot air equipment to form sealable seams around the top opening and bottom drain vent holes.

There are a few different FIBC bulk bags manufacturer on the market today. Each has its unique benefits that make packaging your products more accessible and efficient.

One type of FIBC bulk bag is the open-top bag. This type of bag is typically used for products that need to be exposed to air, such as food or flowers. Using an open-top bag lets the customer see what's inside the bag and decide if they want to buy it.

Another type of FIBC bulk bag is the sack-style bag. This type of bag is typically used for products that don't need to be exposed to air, such as electronics or pharmaceuticals. Using a sack-style bag is more compact and can hold more product than an open-top bag.

Finally, there's the film-style bag. This type of bag is typically used for products that need protection from moisture and dust, such as medical devices or clothes. Using a film-style bag is that it keeps the product inside the bag and doesn't allow air or moisture into the product.

The benefits of UN-certified packaging are many. A bag must meet several requirements to be certified, including environmental and social responsibility. One of the main benefits of UN certification is that it ensures a high level of safety for the people who use the products. UN certified bags are also often made from recycled materials, which helps conserve resources. Additionally, UN certification can help reduce the amount of waste produced by packaging goods.

Bulk packaging can be a massive benefit to businesses and help cut down on waste and keep products safe and fresh. Bulk bags are a great way to do this, and they also come with several other benefits.

One of the essential things bulk bags can do is protect products from damage. When products are packaged in bulk, it's much harder for them to get damaged during shipping. This means your products will be safe when they arrive in your customers' hands.

Another advantage of bulk bags is that they can save you a lot of money. You won't have to spend as much on packaging materials, and you'll also avoid having to buy large quantities of any one type of product. This can save you a lot of money in the long run.

Finally, bulk bags can improve your business's overall appearance, making your products look more professional, which can increase sales.

When looking for bulk packaging solutions, few companies can compare to FIBC. We offer a wide range of FIBC Bulk bags suppliers, ideal for various applications. Our bulk bags are made from high-quality materials and are designed to last. Thanks to our innovative design, these bags are easy to open and reduce the time and energy needed to fill and transport your products.

SWL Range: 500 kg to 2000 kg.

The benefits of using conductive bulk bags are numerous. These bags can be used in various applications where wire or cable insulation is needed. They are also perfect for packaging and shipping products that require electrical and magnetic field protection.

Conductive bulk bags come in various sizes and are manufactured in multiple materials. Some standard options include PVC, PE, and HDPE. Each has its own unique set of benefits and drawbacks, so choosing the right option for the specific application is essential.

One of the key benefits of using conductive bulk bags is protecting products from electromagnetic interference (EMI). This includes everything from cellular phone signals to high-voltage power lines. In some cases, EMI can even cause electronic equipment to malfunction. Companies can protect their products from these harmful effects by using a conductive bag.

Another benefit of using conductive bulk bags is protecting products from heat damage. These bags can help keep food items fresh and prevent them from becoming dry or burnt during transport. In addition, they can also help reduce the amount of thermal stress that is placed on electronics during shipping.

Bulk packaging is essential for companies that produce and distribute various goods. Bulk bags are a common way to package products; they come in many different shapes and sizes.

There are several types of bulk bags, including type D bags. Type D bulk bags are the most commonly used type of bulk bag because they are versatile and reliable. They are also known for their robust construction.

Type D bulk bags are made from heavy-duty plastic. The bags have a rectangular shape, measuring approximately 38 by 53 inches. They are usually filled with small items, such as grains, rice, or flour. Type D bulk bags are easy to open and close because they have double zippers, making it possible to fill the bag quickly and easily.

Type D bulk bags are versatile because they can be used for various purposes. They can be used to package products such as food items or raw materials, and they can also be used to package products that require protection from moisture or dust particles. Type D bulk bags are resistant to punctures, making them ideal for use in industrial settings.

Features of FIBC Bulk Bags

FIBC Bulk Bags are a great way to package your products. They are made from high-quality materials and are designed to protect your product. Here are some of the features of FIBC Bulk Bags:

FIBC Bulk Bags are designed to protect your products. They have robust and durable construction, and they feature a flexible design that makes them easy to open and close. The bag is made from high-quality polypropylene material, and it's seam-sealed at all four corners.

The bag won't rip or tear when you open it. And once you've opened it, there's no need to worry about your product getting damaged. The bags can be used to package small items:

FIBC Bags offer numerous benefits to the customers:

Compact packaging that saves space and resources:

Provides a unique product presentation to the customers

Applications of FIBC Bags

FIBC bulk bags are being used in various industries to package and protect items. They are often used in the food industry, where they effectively keep food fresh and protect it from bacteria and other contaminants. In the construction industry, FIBC bags are often used to protect materials during transport. They are also popular in the medical industry, where they are used for packaging medications and other medical supplies.

Specifications of FIBC Bulk Bags

The FIBC Bulk Bags have a variety of specifications that set them apart from other packaging options. First, they are made from polyethylene, a thermoplastic material resistant to tearing and puncturing. This makes them a popular choice for storage and shipping materials, as they are durable and reliable. Additionally, the FIBC Bulk Bags come in various sizes and shapes to fit any need. They are also available in a single-pocket design, perfect for small shipments. Finally, the FIBC Bulk Bags are available with different thicknesses that can be customized to meet your needs. This flexibility in design and choice makes the FIBC Bulk Bags a popular choice.